Value-engineered solutions meet tight tolerances, shorten construction time, and increase solar projects’ lifetime profitability

Solar sites are rarely perfect. As many of the ideal, flat lands for solar installations have already been built on, North American developers face even more challenges: unforgiving rocky terrain, steep slopes, and non-southern facing hills.

Unlike conventional solar racking manufacturers, Terrasmart’s 120-person construction team deploys years of field experience, overcoming site challenges to keep builds moving at a swift pace. By knowing how our products function in the field, Terrasmart has a good level of understanding to drive product advancements that service all land conditions. This invaluable insight captured between installation and product development has allowed our single-axis tracker innovation to thrive, making our construction crew’s lives easier and our customers happier with enhanced products and project returns.

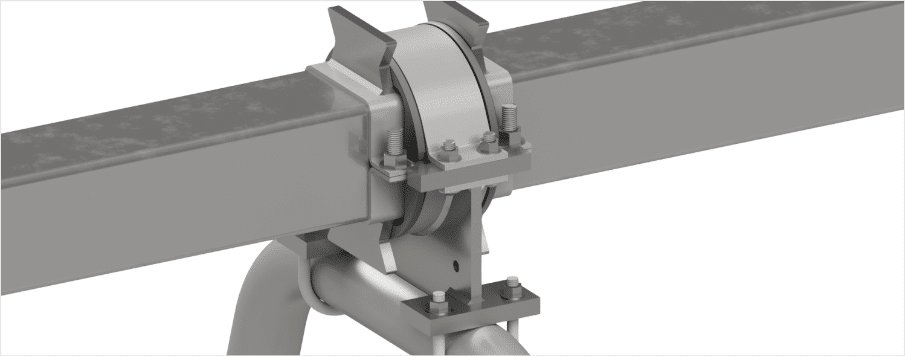

Terrasmart’s SAT TerraTrak enables EPCs and developers to increase value by transforming unusable land into valuable solar assets. TerraTrak’s uniquely adjustable design conquers the steepest slopes while maximizing land potential with built-tough mechanics and intelligent control technology. Our A-frame design can be used with either ground screws to penetrate rocks and boulders, or driven-pile foundations for more versatile situations.

Because we leverage construction insights of our field teams, our in-house feedback loop has directly inspired the design of TerraTrak’s numerous features, leading to quicker installs, improved accuracy, and reduced installation costs.

Here are three examples of how our SAT TerraTrak was directly influenced by field installations:

1) Screw extensions provide the adjustability that construction crews crave

Terrasmart has designed screw extensions to be used with TerraTrak, allowing the height of the ground screws to be vertically adjustable and meet construction capabilities and tolerances. This critical improvement ensures our finished products are installed straight, aligned, and function optimally, even for severe grades.

“What the client says we are getting does not always match real-life conditions. So having that ability to have the adjustability makes a huge difference, so that it not only works but also looks aesthetically pleasing, which the customer really likes,”

— comments Project Manager Sam Decelle on his team overcoming unforeseen challenges.

Suppose a piece of cobble or rock is hit. In that case, the screw extension allows the construction team to maximize the tracker’s slope tolerance with East/West movability and vertical adjustments, avoiding expensive and time-consuming site remediation and design iterations. By perfectly aligning the screws with the extra flexibility from the slotted extensions, the screw is able to easily connect below-grade with the bottom of the tracking system’s A-frame, preventing unnecessary maintenance costs from misaligned rotation and improving the customer’s bottom line.

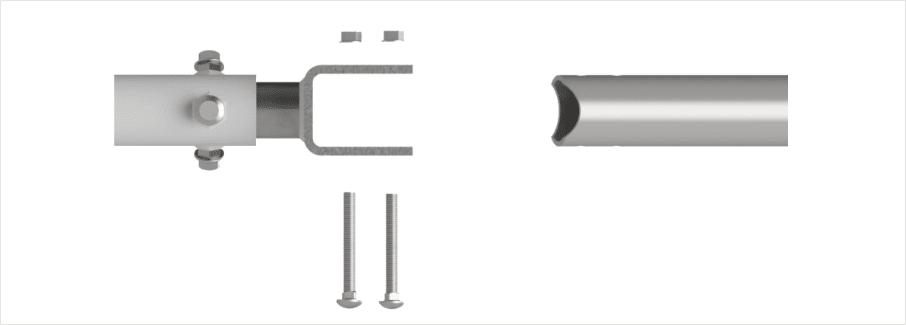

2) Slots in bushing housing assemblies allow for perfect pairing with tracking systems

Bushing housings prevent solar trackers from wear and tear as they rotate. For hilly sites, aligning the tracking system with the bushing housing can be an arduous task, typically involving moving tons of earth and soil to make the site flat. Instead, Terrasmart’s custom-fabricated slotted bushing housing design allows for adjustable alignment with the A-frame tracker to install directly on up to 20% grade slopes.

The benefits of Terrasmart’s slotted bushing housing are highlighted below:

- Accommodates to undulating site terrain with steep slopes

- Reduces the need for expensive and time-consuming grading with a 20% grade tolerance

- Expedites installation process with quick adjustments

- Rotates along the North/South axis to mate with a misaligned tracker

3) Single-axis tracking systems maximize solar performance with consistent reliability

Single-axis tracking systems are the preferred choice to optimize system yield and time-of-use rates to boost production during mornings and late afternoons when solar performance is outside of peak irradiance hours.

However, because SATs have more moving parts than fixed systems, they often present reliability issues. TerraTrak’s system boasts fewer moving parts than other trackers, resulting in lower maintenance and less costs.

“We haven’t had to go back to the drawing board with tracker because we used those field inputs from the beginning, keeping us out of design iterations because we spoke with the construction department beforehand,” emphasizes Toby Holden, a Senior Mechanical Design Engineer who designed Terrasmart’s first commercialized single-axis tracker.

Toby explains in this video how by understanding the problems that the construction team faced, he was able to create a product that ultimately set his team up for success.

The single-axis tracker’s parts have also been designed with maintenance in mind by simply removing a few screws for easy access and quick replacement of gear motors and batteries, saving the client from significant downtime and lost revenue.

Terrasmart continues to put innovation first

Terrasmart has always been a trailblazer – beginning with one of the industry’s first, iconic ground screws. Our innovation continues, with new products coming soon this fall. Stay tuned!