Source: Solar Power World

Challenging weather and tough terrain are the new normal for solar developers, EPCs, and asset owners seeking to manage risks and secure returns. Among the challenges are heavy snow loads, whipping winds, undulating slopes, and rocks threatening reliability and refusals.

EPCs and developers looking to turn arduous sites into valuable assets must juggle complex ground-mount construction risks that can derail margins and project schedules.

It takes both time-tested methods and innovative approaches to manage risks and secure returns in harsh conditions. With more than a decade of experience designing and building utility-scale PV systems in rugged environments, Terrasmart has learned the hard-knock lessons required for success. Here we share insights into managing wind and ensuring tracker reliability followed by a look into bringing it all together on-site.

Get wind of tracker reliability

Single-Axis-Trackers (SATs) are designed to withstand wind. But as module size increases, so do wind impacts.

Wind testing is critical to discern how gales, turbulence, and shifting directions can affect design and production. Optimizing energy yield and mitigating uncertainty requires properly accounting for these effects. Employing advanced wind tunnel testing techniques ensures long-term performance while meeting financial targets.

Our team spent 500+ hours in wind tunnel testing to design a uniquely versatile tracker that can outperform challenging weather. Our TerraTrak 1P and 2P are built to reliably withstand the worst Mother Nature can dish out while enhancing installation speed and overall value:

- Versatile above and below grade: Our foundation-agnostic solution, paired with legs offering 36 inches of vertical adjustability, provides maximum flexibility above and below grade, easily overcoming undulating topography and reducing grading requirements.

- Tough by design: TerraTrak’s proven reliability can sustain wind speeds up to 150 mph, snow loads of 100 psf, and frost depths plunging below 60 inches.

- Easy to install: With a 73% reduction in bushing assembly parts, 30% to 50% fewer foundations per megawatt, and easy wire management, TerraTrak offers industry-leading speed and cost advantages.

- Eliminate refusals: With 1.5 million ground screws installed, 350 MWs of proven reliability, our field team offers 14 years of experience eliminating refusals on tough sites.

Smart controls maximize production while protecting assets

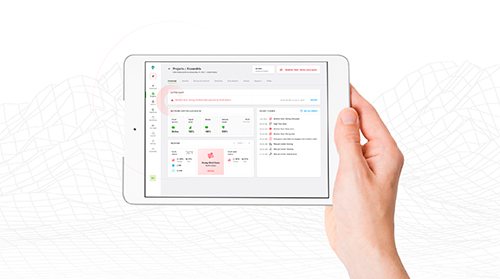

TerraTrak works in tandem with an intelligent control system to maximize energy yield through efficient land use. The PeakYieldTM system is designed to optimize the tracker’s performance and reduce operating costs with live data output and smart-tech controls. It maneuvers each tracker row to limit shading and maintain optimum exposure and production.

PeakYieldTM uses cloud-based data to support predictive analytics and maintenance, addressing issues before they disrupt production — and revenue. PeakYieldTM delivers unique advantages to proactively track, alert, stow, or troubleshoot production, including:

- Real-time data and dashboard with email and SMS notifications to guide predictive and corrective maintenance.

- Smart weather API and on-site sensors forecast and monitor snow, wind, and flood to alert when trackers should be stowed. Optimized 60-degree stow angle helps distribute and stabilize loads across rows.

- Remote software updates and a real-time cellular connection allow easy enhancements and remote troubleshooting to keep systems up-to-date, reducing truck rolls onsite.

- A proprietary AI cloud runs predictive analytics to reduce downtime and maximize yield.

Bringing it all together to overcome the extremes

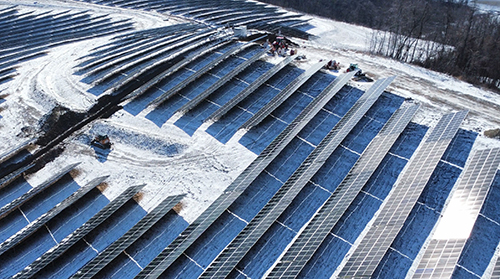

With nearly triple the average U.S. snowfall, the 6.5-MW Sangerfield project in upstate NY presented daunting challenges. Terrasmart’s team began the five-month installation contending with snow and frozen ground; by the time the last of the site’s 17,038 modules went up, the team was having to mow fast-growing grass. Between those two extremes, Terrasmart’s installation crew dealt with thick mud that threatened to mire its heavy equipment. Because it once was a farm, the site was also was pocked with clay drainage tiles and flood zones.

This complex project required a flexible tracking solution built to handle the extremes: flexible, durable mechanics, and intelligent controls. Known for its performance on precipitous terrain, environmentally sensitive land, and frost-laden soils, TerraTrak is the only A-frame SAT that can use either ground screws or driven-pile foundations. At Sangerfield, ground screws were the only way to cut through underground drainage tiles to eliminate refusal risks. To contend with 20% north/south slopes, Terrasmart engineers proposed a creative solution: Divide the project into two sub-sites of 113 rows and design for a 60-degree tilt angle.

Terrasmart’s sophisticated software simulated the most cost-effective design for the site’s 105-mph wind profile and considered varying force angles. Robust snow-load tests ensured success despite 52 psf conditions, maximizing energy output and returns.

To keep the project on schedule, Terrasmart staggered work through seasonal shifts, and used its proprietary screw drilling machinery to secure foundations without refusals. To ensure long-term monitoring, asset operators leverage PeakYieldTM to assess each row’s production across the site’s steep hills.

Solar success no matter how severe the conditions

As one of the only racking companies that can support the entire project lifecycle, Terrasmart brings a deep understanding of PV success.

From start to finish, we’re there with design optimization software, integrated foundation, racking, and eBOS systems, and the expertise to execute projects with in-house installation crews and proprietary equipment.

With over 20 GWs of solar deployed across 4,900 utility and C&I systems, Terrasmart’s end-to-end solution helps customers boost project value on even the toughest sites.

Together with our partners, we push the innovation limits to help you succeed and continue to drive powerful progress for solar anywhere.