Unpacking the Value of Terrasmart’s Ground Screws

Ground screw foundations have been successfully deployed in ground mount solar applications for decades. Asset owners, developers and EPCs of large scale systems have turned to ground screws for reliability in challenging conditions like rocky soils and frost heave conditions that present costly refusal risks. There is a cost benefit to using ground screw foundation when upfront cost could exceed traditional pile systems. The long-term value has been proven and many racking manufacturers now offer ground screw foundations to expand opportunities on arduous sites.

Terrasmart is known as one of the first providers of ground screw foundations in North America, and leads the industry to this day.

We recently sat down with John Goetz, Sr. Product Manager of Ground Mount, and Richard Van Fleet, Director of Field Operations, to unpack the value of Terrasmart’s ground screw offering and explore in detail the long term value and levelized cost of energy (LCOE) advantages for ground mount PV.

1. Understanding that other racking companies now also offer ground screw foundations – What would you say makes Terrasmart’s solution unique?

Offering a “real” solution versus a “paper” solution. Some of Terrasmart’s competitors may claim to offer ground screws and may even provide what seems like a competitive proposal. Oftentimes these proposals lack the breadth and depth of our fully-wrapped solution and contain hidden costs and schedule risks.

By breadth, I mean the variety of fixed tilt and tracker solutions that we can offer clients on ground screws—including our fixed Glide Agile system, and our SAT’s TerraTrak 2P and 1P. “And by depth, I’m referring to the unique depth of our knowledge and proven experience – our team has installed nearly 2 million ground screws across 5800+ projects over a decade of large-scale PV experience,” states John. We’ve had many customers come to us after experiencing hidden costs and setbacks with other providers who can’t deliver what they quoted.

Richard adds, “There are no substitutes for real world experience. Our teams have installed ground screw systems all across the U.S. in soils including clay, ledge, rock, igneous rock, silt, sand, glacial till, decomposed granite, volcanic rock, coral, and more. We’ve successfully installed in every type of terrain imaginable.” For further detail about installing on a flood-prone and high slope site, read our project case study.

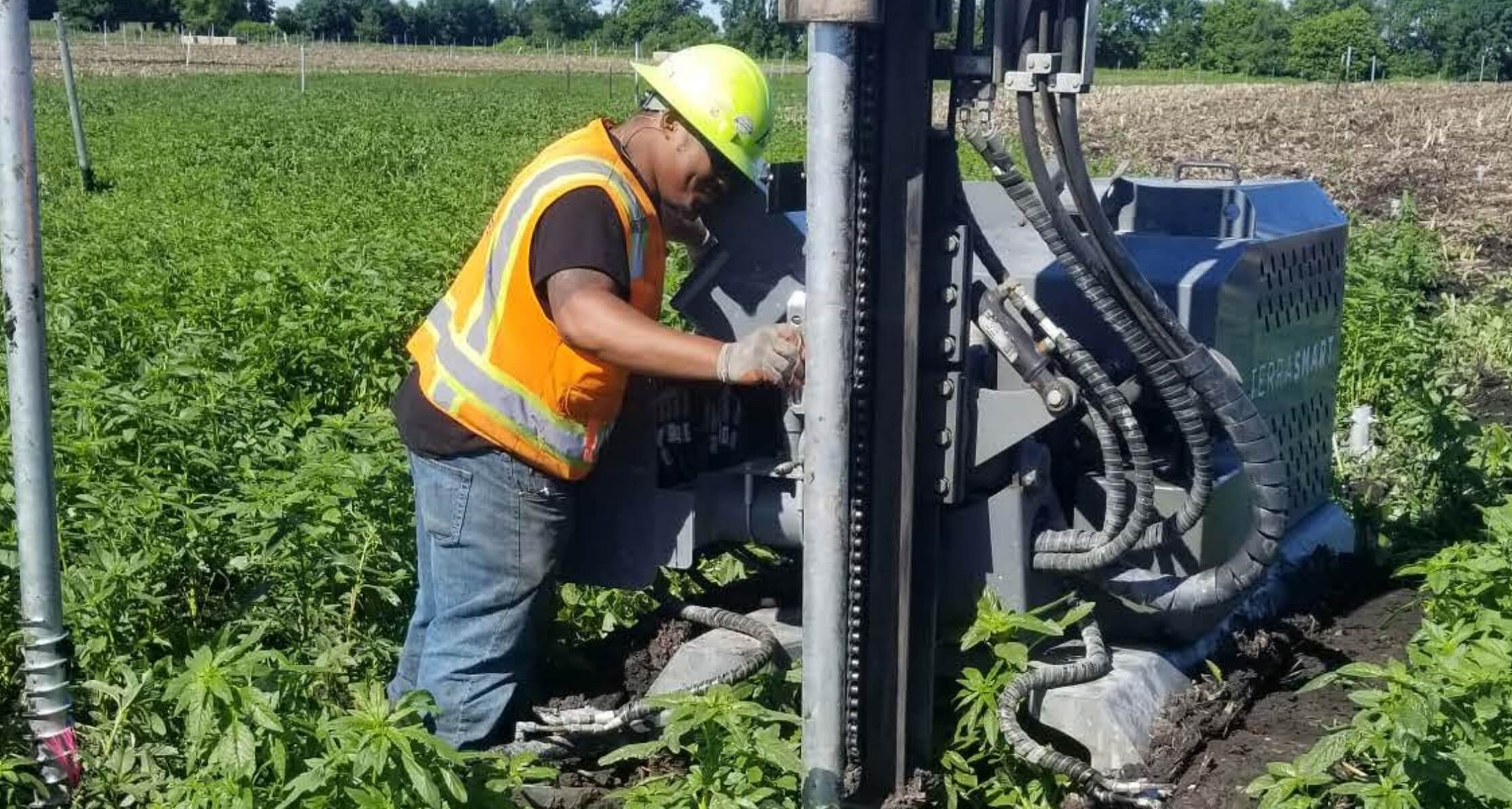

Our fleet. We have 90+ pieces of specialized, proprietary equipment that optimizes the installation of our ground screws. In addition, we have a higher bandwidth that exceeds any other provider. Our project timelines are more predictable as we eliminate schedule risk by pre-drilling every foundation.

Another differentiator is our torque value: “Terrasmart is the only company that can verify and confirm torque capacity during a screw’s installation phase without adding an additional step,” said Richard. Other providers need to do this ahead of time which adds to the schedule and cost – we can verify all our screw’s torque value upfront in one swoop. Verifying torque is key to confirming the quality of the installation so that the foundation will support the rack for the duration of its design life.

2. How does this translate into less risk for asset owners, developers, and EPCs?

There are three ways that our ground screw solution mitigates risks and they are all critical to a project’s success:

- Schedule risk – Terrasmart provides an end-to-end solution, including the installation. Using our experienced teams, we design, plan, and perform the installation to bring the project in on-time. We perform all aspects of the installation including survey, screw installation, and rack construction. Many of our competitors do not perform surveys, which can lead to challenges related to screw placement and costly rework. Furthermore, ground screws have a higher daily install rate (25 – 50% higher) than traditional driven piles, which also aids condensed schedules.

- Technical risk – Terrasmart provides the foundation and the rack as an integrated solution. Our competitors provide the foundation and then another company puts their racking systems on top. This introduces technical risk into the project. For example, if the rack and the foundation interface present compatibility or integration challenges, who owns the issue? The foundation provider or the racking manufacturer? This risk does not exist with Terrasmart as we own the entire process. In addition, this makes for fewer warranty claims which aids in expediting schedules.

- Long-term risk – Terrasmart is backed by Gibraltar, a NYSE traded firm with a 50+ year track record and strong balance sheet. Customers that choose Terrasmart can rest assured that products, spare parts, and support will be available for years to come. This uniquely bankable position helps asset owners gain the confidence they need in operating a system for 20+ years.

3. How does it lead to overall LCOE advantages over the life of the system?

This is key and represents an intangible benefit that yields proven advantages often mentioned by our customers. Working with an experienced partner like Terrasmart leads to unique levelized cost of energy (LCOE) benefits:

- John remarks, “Because Terrasmart delivers an integrated material and installation solution, we ensure fewer surprises, schedule slips, and change orders – all of which lower overall installed costs.”

- This level of partnership includes a more responsive and clearer technical support, dedicated to each project resulting in less downtime. For example, if there are any questions or challenges with the racking or foundations, Terrasmart owns it and has a team of experts ready to support our products.

4. What does Terrasmart’s installation team have – or what can it deliver – that other providers do not offer?

Our Training. Even when our team is selected to only install the foundation but not the racking, we schedule overlap with the crew that will be constructing the racking to ensure they understand the system, tolerances, and installation procedure before starting. We are team players to meet our clients’ needs and this extra step shows that.

Terrasmart is unique in that we have our own fleet of installation machines that are designed and built specifically for Terrasmart, along with our highly trained operators. Because other manufacturers do not own their fleets, they lack the feedback loop needed to develop, innovate, and improve as quickly as we can.

We developed our own proprietary processes using the experiences learned from installing nearly 2 million ground screw foundations across the country. Every operator is trained using this process to create uniformity and provide the same level of quality our customers have become accustomed to.

Our Equipment. Our ground screw driving equipment has been custom designed for the solar industry to ensure the job can be completed faster. “Terrasmart’s system is more mobile and only requires 1-person per machine, making it 1.5 times faster than a traditional skid-steer with attachment per hour.” – John

For our TerraTrak offerings, our proprietary software PeakYield™ gives customers visibility into real-time site conditions, enabling less downtime and higher production.

Our Processes. Our team of construction and project managers use project management software to plan every aspect of a job. We have also designed many custom jigs and developed customized processes to enhance productivity and quality.

Our Offering. Terrasmart is unique in offering 6 different screw sizes (1425 metric, 1600, 2100, 2380, 2600, 2900). This broad portfolio with many different screw sizes sets us apart because we can value engineer projects and custom-design screws with different thread profiles based on subsurface conditions and environments. “This provides more confidence to contend with conditions like frost heave, corrosive soils, heavy snow loads, high wind tolerances, and other extreme challenges or unforeseen risks.” – Richard

We also offer a variety of Fixed Tilt systems (high-wind, high snow) and TerraTrak 2P/1P on ground screws. Most of our competitors are focused on Fixed Tilt and/or just a portion of the tracker market.

Because our systems are designed for flexibility we pair ground screws with both fixed and SAT systems that offer a high 20° slope tolerance. This is hugely significant in reducing grading costs and increasing yield on hilly terrain. Read our case study on Navigating Slopes for a Competitive Edge to compare varying slope tolerance systems in different topographies.

5. Is there a specific project that really brings this value proposition to life?

There are many. A couple that come to mind are the East Point & High River projects, both completed in 2023 in upstate New York using “special thread” screws. Combined, these two projects represent a 250 MW capacity. We were able to cut costs for our client by customizing the thread thickness (pitch) on a 2100 screw using a proprietary formula.

The 82-MW East Point Solar project using our 2P tracker system was designed for a wide-ranging snow load from 54 psf to 62 psf. Because of the wide range in elevation, snow loads were increased by 2 psf for every 100 feet above the 1000 feet elevation. High wind speeds up to 107 mph required special wind and corrosion design for 25 years.

High River, a 150-MW system using our fixed-tilt GLIDE Agile portrait racking system also included customized screws.

6. Can you share any parting thoughts to help developers and EPCs evaluate options?

John declared, “I think when exploring foundation and racking partners, having ‘one hand to hold’ from start to finish makes a huge difference in mitigating risks, resolving issues, and achieving a better and faster build.”

At Terrasmart, we design from the start using the same team that will lead the project through to the finish line. We are accountable to make the project successful and do not point fingers if challenges arise. Our team uses our proprietary machines and methods to install the foundations and the racks, and our screws are trusted to last the lifetime of the project – in any soil, any weather, anywhere.

About the Authors

John Goetz

John Goetz is focused on all aspects of the ground mount portfolio, including fixed-tilt and TerraTrak.

Richard Van Fleet

As director of Field Operations, Richard oversees the execution of all field operations and has been leading the construction team for a decade.