Terrasmart’s Top 10 Accomplishments of 2022

We are excited to launch into 2023 with a fresh roll-up of product advancements and new projects. As we’re invigorated with new-year energy, we wanted to pause and reflect on 2022’s top highlights.

From completing milestone projects to energizing our teams, Terrasmart has built on its mission: powering progress through partnerships. We are grateful for our teams’ many accomplishments wherever they shine — on the manufacturing floor, our solar project sites, or the industry stage. Here we recognize the year’s top 10 achievements:

1. Exhibited under unified brand for the first time

First at February’s RE Northeast in Boston and then in the fall at RE Plus in Anaheim, we were elated to bring our four legacy brands together under the new Terrasmart banner — especially after the pandemic’s long hiatus, away from solar colleagues and friends. Check out our brand manifesto video for more on Terrasmart’s unique value and synergy!

2. Installed 1.1 GWs of clean energy this year

With a razor-sharp focus on quality and execution, our product, manufacturing, and field installation teams have worked hard to meet aggressive targets such as our ground mount team installing over 250,000 ground screws and 73,000 driven piles. Additionally, our Solar Instant Feasibility Tool (SIFT) was used to plan for 1,600 gigawatts of solar project capacity. Across all business units combined, Terrasmart completed nearly 1,000 projects in 2022 supporting more than a gigawatt of new solar capacity across the country!

3. Supplied Chicago’s largest carport rooftop, the first on the city’s Southside

We are honored to have been selected by the Chicago Urban League to supply the non-profit’s rooftop and carport system. At 213 KWs, the system is Chicago’s largest commercial PV project and the first on the Southside. The League is one of the country’s oldest urban advocacy organizations for the advancement of African Americans. This project highlights its commitment to supporting the community’s access to renewable energy.

4. Won Editor’s Choice Award for innovative Non-Wires Alternative project

Terrasmart supplied the mounting for National Grid’s innovative non-wires alternative project in Cicero, N.Y. This landmark 15-MW solar system won Solar Builder magazine’s Editor’s Choice Award for Grid Service. The project uses 40 MWh of energy storage instead of more expensive transmission and distribution upgrades. It is the first project in the United States to utilize batteries and solar as non-wires alternatives to more expensive transmission and distribution upgrades.

We are proud to play a part in this disruptive new business model for utilities as they navigate grid upgrade challenges. This solution allows utilities to leverage solar-plus-storage to forego typical upgrades, improve grid reliability, and reduce dependence on gas-fired plants.

5. Launched new Green Team initiative

Our core business is designing, manufacturing, and installing renewable energy as sustainably as possible. We launched our Green Team initiative to do just that. From steel recycling and reducing shipping waste to community stewardship programs at our various sites, we are expanding our impact to lower our footprint. The initiative includes other programs such as “Terrasmart Cares,” a volunteer program to educate employees and support sustainability efforts at our sites and in our communities. Future endeavors will include installing new EV charging stations and low-emission vehicle priority parking spots at all main office sites, upgrading our field vehicles to hybrid and all-electric vehicles, as well as roof-top solar panels to power our business locations across the U.S.

6. Helped construct the country’s largest landfill PV project

Terrasmart is honored to have been part of North America’s largest landfill solar project at Mount Olive, N.J. with long-term partners CS Energy, CEP Renewables, and Lindsay Precast, Inc. Terrasmart brought its ballasted system expertise to the 25.6-MW project, designing the system with our GLIDE racking product. We also supplied the eBOS components, including 148 combiner boxes.

There are more than 10,000 closed landfills in the United States. While the EPA reports an 80% increase in the number of landfill PV projects over the last five years, capped landfill systems require specialized design and construction execution. The Mount Olive project now serves as a model for how to bring new uses to thousands of other closed and dormant landfill sites throughout the country.

7. Authored industry-first study comparing foundation options in utility solar

With our unique experiences and field knowledge about both ground screws and driven piles, Terrasmart was able to conduct the industry’s first study comparing material and installation costs for each foundation option. Our lead engineers compared two 10-MW sites — one with limited slopes and soft soil, and the other with a more rugged rocky profile that posed high refusal risks.

The result: Pile refusals sharply affect cost and installation schedules. Above a 29% pile refusal rate, ground screws are more cost-effective. But from a schedule perspective, the break-even point is much less forgiving: A refusal rate above 7% adds costly construction delays — each additional 15% of pile refusals adds another day to the schedule.

8. Spearheaded diversity and inclusion practices

Terrasmart is building a thriving culture of changemakers. Our commitment to shepherding the growth of future leaders in PV manufacturing is achieved in part through increasing diversity and inclusion within our company. Team members like Greta Urbanek are the driving force behind our success, bringing their passion for elevating people into leadership roles. See one of many examples showing how Terrasmart builds a diverse and inclusive workplace where women and underrepresented minorities are valued and respected.

9. Committed to American-made PV manufacturing

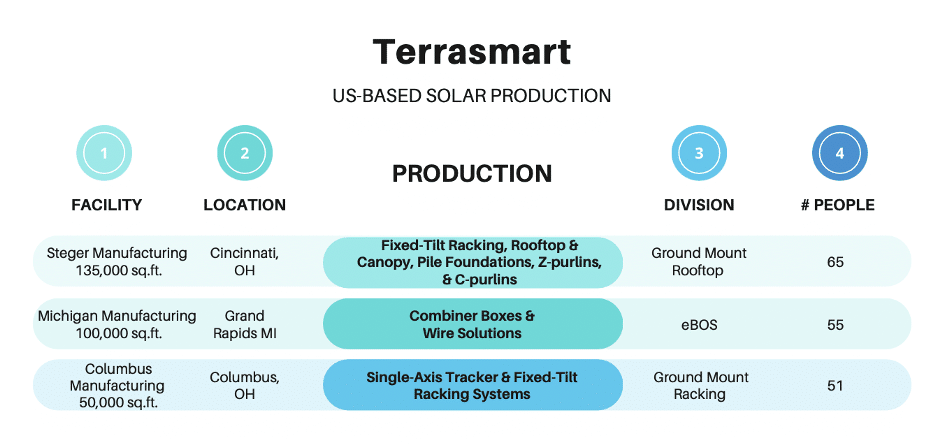

As the Inflation Reduction Act re-energizes the U.S.-based solar production, Terrasmart is proudly leading the charge with its 15-year legacy of domestic design, manufacture, installation mounting, and eBOS solutions. Our high-velocity American manufacturing means we can meet tight construction timelines as we create lower-cost, built-to-last solar. And because we control our vertical integration, we also control the supply chain, making us transparent and dependable.

Our renovated 50,000-square-foot facility in Columbus, Ohio, is equipped with cutting-edge equipment to manufacture Terrasmart’s single-axis tracker and fixed racking components. New equipment investments in our eBOS division allow us to meet demand and drive growth. The recent addition of two new roll formers at the Cincinnati, Ohio, plant is allowing our manufacturing team to keep up with the current demand, making way for competitive lead times and even allows more flexibility with each project’s design. With an eye on the future, our supply chain team is working rapidly to onshore and certify all remaining foreign tracker components and hardware in early 2023.

10. Continuing to lead in the Northeast

With 12 years of experience and 1.1 GWs installed in the last year alone, the Terrasmart team understands the Northeast’s complex challenges. In 2022 we continued our growth by installing 80 – 85% of our ground mount projects in the Northeast region, as well as authoring numerous best practice guides for solar success in hilly, rocky, and frost-heave prone environments.

For solar developers and asset owners, the Northeast’s harsh weather and tough terrain can present complex factors that require careful consideration at every stage of development to secure returns and bankability. For EPCs striking the right balance between risks and rewards, Terrasmart Director of Construction Randy Smith offers actionable strategies to deal with refusals, steep slopes, and wicked weather conditions.